The Romanian

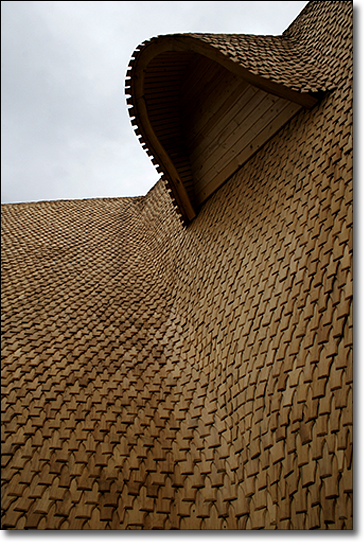

Hand-split shingle

A material used for covers and obtained from fir.

Akin to ‘sindrila’ and ‘dranita’, which are other materials used for the same purpose, but different about sizes as well as processing and assembling techniques.

The cover of the hand-split shingle can be brought in by way of 3 or more layers. The proposed type is cloven, handcrafted and assembled in 5 layers with standard dimensions of 85/330/5 mm.

Each split form demands a minimum of 8 passings with ‘cutitoaia’ (a metal blade with handles) to become a finite material. These procedures are done at the hand-split shingle horse.

The hand-split shingle forms which are required for laying a ridge are as follows: the camp shingle, the crest shingle, the overhang shingle and the valley shingle.

The forms can be mounted with stainless steel or double galvanised nails (with hidden nail) on a board surface, laid-down with breaks of 4 cm lenght. This spacing between the support boards ensures good ventilation of the shingle, while having a role for the construction in case of tying the mounting platform (the shingleman seat). Under shingle’s support board surface there is a minimum 5 cm of layer left for ventilating the cover. By employing the shingle to ridges with specific slopes, this support board is in fact the shingle’s revetment as well.

The shingle is antibacterially and fireproof treated in special pools and with approved substances. At the end of the placement a wax-based drench in different shades is applied. This final treatment will be performed again after some years when is required by the shingle’s timber. In order to ease the performing of treatment by climber teams, brackets for bracing up their special equipment are provided.

The coating so executed, mounted, treated and serviced over time can have a lifetime of over 60 years.

Akin to ‘sindrila’ and ‘dranita’, which are other materials used for the same purpose, but different about sizes as well as processing and assembling techniques.

The cover of the hand-split shingle can be brought in by way of 3 or more layers. The proposed type is cloven, handcrafted and assembled in 5 layers with standard dimensions of 85/330/5 mm.

Each split form demands a minimum of 8 passings with ‘cutitoaia’ (a metal blade with handles) to become a finite material. These procedures are done at the hand-split shingle horse.

The hand-split shingle forms which are required for laying a ridge are as follows: the camp shingle, the crest shingle, the overhang shingle and the valley shingle.

The forms can be mounted with stainless steel or double galvanised nails (with hidden nail) on a board surface, laid-down with breaks of 4 cm lenght. This spacing between the support boards ensures good ventilation of the shingle, while having a role for the construction in case of tying the mounting platform (the shingleman seat). Under shingle’s support board surface there is a minimum 5 cm of layer left for ventilating the cover. By employing the shingle to ridges with specific slopes, this support board is in fact the shingle’s revetment as well.

The shingle is antibacterially and fireproof treated in special pools and with approved substances. At the end of the placement a wax-based drench in different shades is applied. This final treatment will be performed again after some years when is required by the shingle’s timber. In order to ease the performing of treatment by climber teams, brackets for bracing up their special equipment are provided.

The coating so executed, mounted, treated and serviced over time can have a lifetime of over 60 years.